Accurate fuel level measurement is a critical aspect of aviation safety and efficiency. It ensures that pilots have the information they need to manage fuel reserves effectively, avoid fuel exhaustion, and plan their flights with precision.

However, many pilots and aircraft operators face challenges and misconceptions regarding fuel level monitoring. Some common issues include unreliable readings due to sensor malfunctions, electrical interference, and human error. This article aims to provide an in-depth understanding of different aircraft fuel level systems, their importance, and how advancements in technology are addressing these challenges.

Why Accurate Fuel Level Measurement is Crucial in Aviation

The most obvious reason for accurate fuel level measurement is safety. Ensuring that an aircraft has sufficient fuel to reach its destination, including reserves for emergencies, is paramount. Accurate fuel readings help prevent situations where a plane might run out of fuel mid-flight, which could lead to catastrophic outcomes. Managing fuel reserves effectively is essential for both short-haul and long-haul flights, where unexpected weather changes or diversions could increase fuel consumption. Leaking fuel tanks or loose fuel caps could also cause fuel exhaustion, as detailed in this testimonial. If fuel gauges need only be accurate at zero, the late Mark Colman would have lost his life then, along with his wife. Tragically, Mark later lost his life in a non-fuel related accident.

Impact on Flight Planning and Efficiency

Accurate fuel level data is crucial for precise flight planning. Pilots rely on this information to calculate weight, balance, and range, all of which impact the aircraft’s performance and efficiency. An accurate understanding of fuel levels allows for better fuel management strategies, reducing unnecessary weight and improving overall fuel efficiency. This not only saves costs but also reduces the environmental impact of flights.

Regulatory Requirements

Compliance with aviation safety standards is another critical reason for maintaining accurate fuel level measurements. Aviation authorities worldwide, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), have stringent regulations regarding fuel management and safety. Aircraft must be equipped with reliable fuel level monitoring systems to meet these standards and ensure passenger and crew safety.

Types of Aircraft Fuel Level Systems

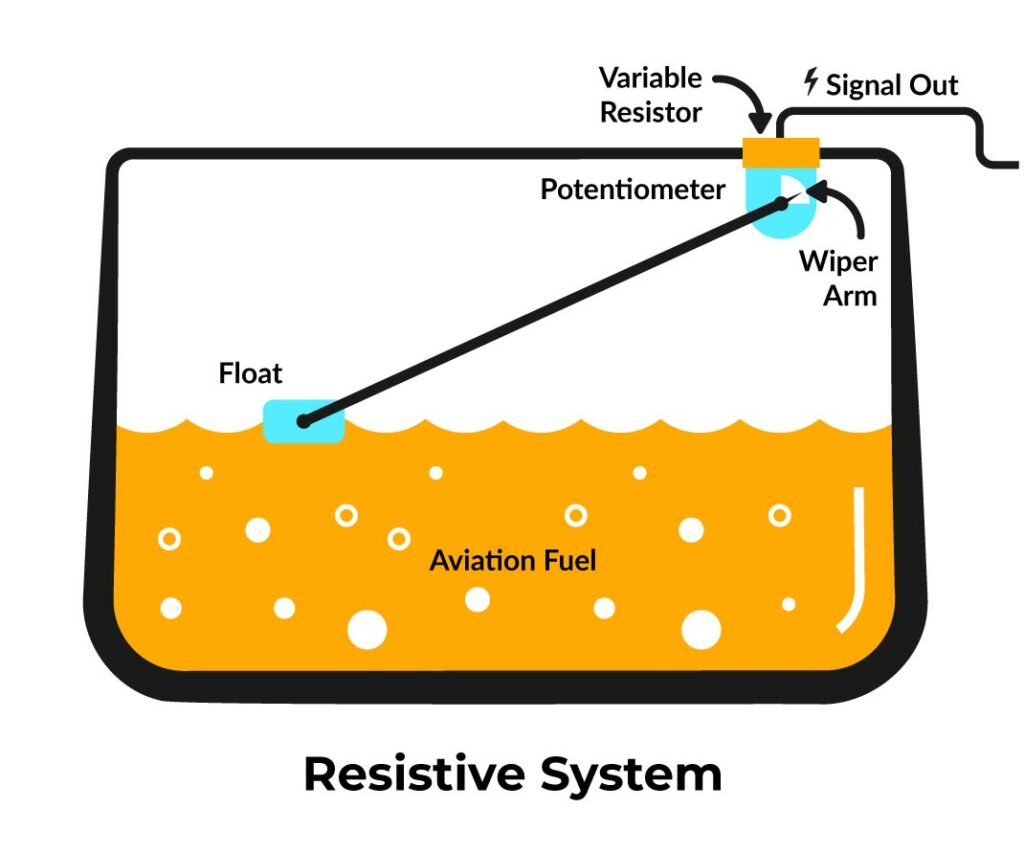

Traditional resistive sensors are among the oldest and most commonly used systems in aircraft. These sensors rely on a floating mechanism connected to a gauge, which indicates the fuel level. While resistive sensors are simple and cost-effective, float-type sensors are prone to inaccuracies due to wear and tear, corrosion, contamination, fuel sloshing, and calibration issues. One of the greatest hazards of traditional resistive sensors are electronics in the fuel tank.

Electrical Systems: Capacitive and Resistive Sensors

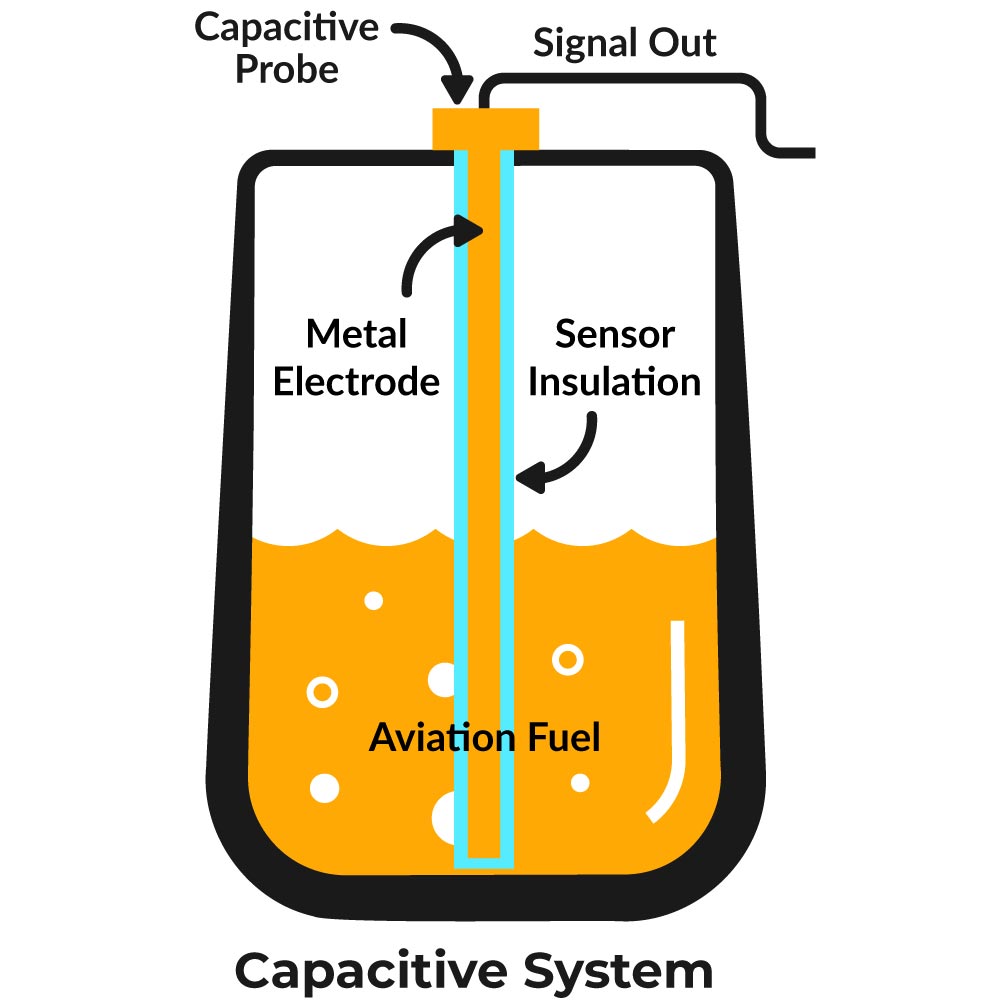

Capacitive sensors measure fuel levels by detecting changes in capacitance caused by the fuel’s presence. These sensors can be more accurate than mechanical (resistive) systems and less susceptible to wear. Resistive sensors, on the other hand, measure fuel levels based on resistance changes in a circuit. Both types have their pros and cons; capacitive sensors are highly accurate but can be more expensive and sensitive to fuel type variations, while resistive sensors are more straightforward but less precise.

Digital Fuel Level Systems

Modern advancements have led to the development of digital fuel level systems, which offer enhanced accuracy, reliability, and integration with aircraft avionics. Digital systems often use advanced sensors, such as magnetic resistive sensors, which provide precise measurements and are resistant to various operational factors. All CiES fuel sensors employ magnetic resistive technology.

Comparison of Different Systems

When comparing these systems, digital fuel level systems stand out for their accuracy and reliability. Mechanical systems are cost-effective but require frequent maintenance and are inherently hazardous with electronics in the fuel tank. Electrical systems offer a balance between cost and accuracy but may still face issues like electrical interference and issues with fuel type variations. Digital systems, though initially more expensive, provide long-term benefits in terms of reduced maintenance, enhanced safety, and integration capabilities. View a comprehensive comparison here.

Advancements in Aircraft Fuel Level Measurement Technology

Modern digital fuel level systems have revolutionized fuel measurement by offering precise, real-time data. These systems integrate advanced sensors and digital displays, providing pilots with accurate and easy-to-read fuel level information.

Benefits of Using Magnetic Resistive Sensors

Magnetic resistive sensors have become popular due to their enhanced accuracy, durability, and resistance to fuel type variations. These sensors are less prone to wear and can provide consistent readings over a wide range of operating conditions.

Modern fuel level systems can integrate seamlessly with aircraft avionics, providing real-time data and alerts directly to the cockpit displays. This integration enhances situational awareness and allows for better decision-making.

Maintenance and Calibration of Fuel Level Systems

Regular checks and calibrations are essential to ensure that fuel level systems provide accurate readings. Neglecting maintenance can lead to sensor degradation and inaccurate data, compromising safety. CiES fuel senders are self-cleaning to assist with this issue.

Best Practices for Maintaining Different Types of Systems

Each type of fuel level system has specific maintenance requirements. For instance, mechanical systems require more frequent inspections and part replacements, while digital systems need software updates and occasional recalibrations. CiES fuel sensors shouldn’t need recalibration unless there has been a change in instrumentation.

Tips for Troubleshooting Common Issues

Common issues such as sensor malfunctions, electrical interference, and calibration errors can be addressed by following the manufacturer’s guidelines and conducting regular inspections.

How CiES is Revolutionizing Fuel Level Measurement

CiES has been at the forefront of fuel level measurement technology, offering innovative solutions that address the shortcomings of traditional systems for over a decade. Their fuel sender technology utilizes advanced magnetic resistive sensors to provide precise, reliable, and consistent fuel level readings. Their success in aircraft safety has been featured in several magazine articles and online TV programs.

Key Features and Benefits

CiES fuel sender technology is known for its reliability, accuracy, and ease of installation. It is compatible with various aircraft types and can be integrated into existing avionics systems, providing real-time data and alerts. Nearly 700 aircraft models have been approved by the FAA for retrofit and can be viewed in our STC/AML. This technology has been praised by aircraft owners and operators for reducing maintenance costs and enhancing safety.

Case Studies or Testimonials

Several aircraft owners and operators have shared their positive experiences with CiES Inc.’s fuel sender technology, citing improved fuel management, reduced maintenance, and enhanced safety as key benefits. You can view over 50+ testimonials here.

Choosing the right fuel level system is crucial for ensuring safety, efficiency, and regulatory compliance in aviation. Modern solutions, such as those offered by CiES, provide enhanced accuracy, reliability, and integration capabilities. For aircraft owners and operators looking to upgrade their fuel level systems, considering a modern, digital solution could significantly improve safety and operational efficiency.

For more information on innovative fuel level measurement solutions, explore our range of fuel senders or contact us for a consultation. Sign up for our newsletter and follow us on social media to stay updated on the latest advancements in aviation technology.

Share this:

About CiES Inc.

Established in 2012, CiES is now the largest supplier of aviation fuel quantity probes and senders. They are the recognized leader in the design, development, certification, and manufacture of electronic sensor solutions for original equipment manufacturers, as well as direct-to-market consumer products. Through the creative application of cutting-edge technologies, CiES creates complex end-to-end solutions. This is a company that is changing the game in aviation technology and revolutionizing the way we navigate the skies. Aiming at future growth and innovation, CiES is pushing the boundaries of what is possible.